ASTM E2179 – Standard Test Method for Laboratory Measurement of the Effectiveness of Floor Coverings in Reducing Impact Sound Transmission Through Concrete Floors

By Jordan Strybos, Intertek, York, PA

ASTM E2179: Standard Test Method for Laboratory Measurement of the Effectiveness of Floor Coverings in Reducing Impact Sound Transmission Through Concrete Floors. Simply put, this standard is used to characterize the specific acoustic benefit of floor covering products when installed on a concrete slab (or, in another manner of speaking, how much quieter does my concrete floor system become when I install a given floor covering on it?). The single-number rating produced by an ASTM E2179 test (calculated with reference to the Method ASTM E989) is DIIC, signifying the change in impact sound reduction introduced by the inclusion of a given floor covering on a concrete floor system. The DIIC rating is somewhat unique compared to other common laboratory sound transmission metrics (STC and IIC, for example) because it represents the acoustic benefit specific to the floor covering product, rather than the acoustic performance of an entire partition or floor/ceiling system. For this reason, the ASTM E2179 test method can be quite helpful in direct comparisons between floor covering products.

The ASTM E90 and ASTM E492 tests (yielding STC and IIC ratings, respectively) are specifically designed to be applicable test methods for a wide variety of building products. These standard test methods are useful because they do not limit the types of products that can be evaluated; the methods can be used for any product that would be a part of a partition dividing spaces within a building. Floor coverings, structural members, insulation, door panels, windows, gypsum board, and many other products can utilize the standardized methods of measurement detailed in these tests. The tests simply measure the acoustic performance of the entire separating partition between two spaces. Due to this wide-ranging applicability, though, the use of the STC and IIC metrics to directly compare specific products (or individual elements within those partitions) can present a challenge.

If, for example, one wanted to compare two different gypsum wall panel products, simply comparing two separate STC test results featuring these products is not necessarily as helpful as it may initially appear to be. The two STC tests for the products could theoretically have these wall panels featured as elements in wildly differing wall systems. Stud spacing, resilient mounting, cavity size, insulation, and a host of other factors all play a role in the acoustic performance of a wall system, and changes in any of those factors will affect the result of the test. With so many potential variables within the partition, the only way to properly analyze the differences between these two wall panel products would be to compare two tests where the only changed variable is the wall panels themselves. At surface value, this seems simple enough to do, but unless the manufacturers of these products are both intentionally aiming for a direct comparison between their products, finding test results that are perfectly comparable can prove to be a difficult task.

This challenge of identifying directly comparable test results has historically been a very prevalent issue in the world of floor coverings, where there is a multitude of differing structures upon which floor coverings can be installed. For this reason, the ASTM E33 committee strived to create a standardized method of comparing floor coverings specifically, to create a test method that would remove the endless potential variables between published tests so that a consumer, contractor, or consultant would have easily digestible comparative data between all floor coverings. Around the turn of the millennium, the seeds of the ASTM E2179 test method were planted, and the test became an official standard test method in 2001.

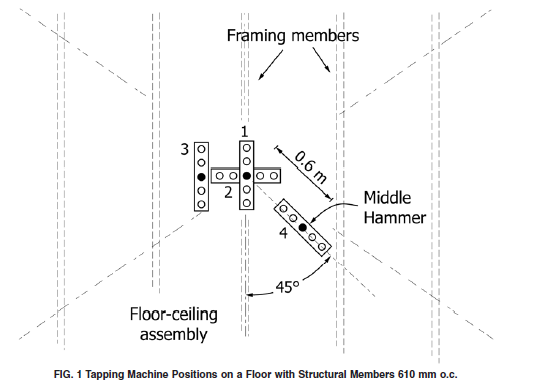

The focus of this test method is solely on the effect that floor coverings have on the impact sound transmission through the floor system. This is due to the fact that floor covering changes bear very little change (if any at all) on the airborne acoustic performance of a floor/ceiling system, making it unnecessary to analyze that performance change. Focusing on the impact domain led the group within the ASTM E33 committee to develop a test method that incorporated the test method already present in ASTM E492 testing, utilizing a standardized tapping machine as the source of impact vibrations in the floor/ceiling system.

The premise of the procedure is simple: in order to characterize the added benefit of the presence of a given floor covering, one simply conducts an IIC test on a floor system without the floor covering, and conducts a second IIC test on the system with the inclusion of the covering. The measured improvement of the system is then analyzed at the third-octave band level and put through a series of calculations to yield the DIIC rating, a single number representing the added acoustic benefit from the floor covering. There is one important distinction to make, though: the addition to the performance of the system will vary based on the baseline performance of the system itself (without the floor covering). With improvement in sound transmission reduction being exponentially more difficult as performance increases, the measured improvement could theoretically get smaller if the covering was tested on a system that already effectively reduces impact sound transmission.

To ensure direct comparability between all ASTM E2179 tests, the choice was made to have a 6” concrete slab as the default floor system. For this reason, the title of the standard clearly states that the effectiveness that is being measured is specific to concrete floors. Discussions are ongoing within the ASTM E2179 task group to potentially increase the scope of the test method to include a lightweight wood structure option (essentially allowing one to calculate a DIIC rating for lightweight structures, rather than concrete structures), but this has not become a reality (for now, at least).

One recent addition to the test standard that is important to note is the addition of high-frequency impact metrics. With the adoption of high-frequency impact metrics (HIIC and DHIIC) into ASTM standards in 2020, the potential for inclusion of high-frequency analysis within this test standard (as well as ASTM E492) was immediately discussed. The high-frequency metrics seemed particularly well-fit for inclusion within the ASTM E2179 test standard, because historical data clearly demonstrates that floor coverings largely have very little effect on impact sound transmission performance in the lower frequency range (below 400 Hz). Further investigation into this showed that the newly-created DHIIC metric not only aligned with existing DIIC ratings, but in many cases more effectively showcased the audible high-frequency differences between products that were otherwise not captured by the DIIC metric alone due to low frequency noise limiting the ratings. For this reason, DHIIC was officially included as a reported metric for ASTM E2179 testing in 2025.

Since its creation in 2001, the ASTM E2179 test method and the DIIC rating have been utilized by floor covering manufacturers to easily and simply identify the acoustic performance of their products, allowing for clear identification of performance and easy comparison of competing products. As the science behind these measurements and methods continues to develop, this method of standardized comparative testing is now being proposed as an option for future new standards for other products as well. Within the floor covering world, a new standard is currently being developed for identifying the added effectiveness of topical underlayment products, which features a similar method of calculating the added benefit of these products. This potential development of future standards for use in characterizing the specific acoustic benefits of the individual elements of building partitions will become quite helpful (especially when used in conjunction with STC and IIC ratings for characterizing the overall acoustic performance of a partition) for more-fully understanding building design, and utilizing this understanding to improve productivity and quality of life, in the workplace and at home.

About the author: Jordan Strybos is a Project Engineer at Intertek’s acoustical testing facility in York, PA. He oversees the Vertical Transmission (VT) test chambers, specifically focusing on floor/ceiling acoustics. Jordan has been overseeing the operations of York’s VT chambers for over 10 years and has been heavily involved in the ASTM E33 committee since 2018, chairing several task groups and serving as subcommittee vice-chair and secretary for the E33.10 subcommittee on Impact Noise and Vibration. The lab at Intertek-York is a state-of-the-art facility that provides highly-efficient testing, excelling in both project-specific test programs and broader-ranging research projects. The VT chambers at Intertek-York offer a lab testing environment for anyone interested in conducting testing per ASTM E90, ASTM E492, ASTM E2179, ASTM E1222, ASTM E1414, ISO 10140, and ISO 15665.