ASTM E492 – Impact Noise Measurement for Floor-Ceiling Assemblies in the Lab

By Jordan Strybos, Intertek, York, PA, and Mike Raley, PAC Intl., Canby, OR and University of Oregon, Portland, OR

Thump, thump, thump, scrape. Your upstairs neighbor just walked to their dining table and pulled out a chair. Kerplunk. Their cat jumped out of the chair. All too often in apartments and hotels we are aware of the movements of our neighbors; every breath they take, every move they make, you’ll be hearing it. Does it have to be this way? No, it doesn’t, but controlling sound, in this case impact sound, is a challenge. That’s why we have acoustical test standards to help us evaluate the acoustical performance of the floor and ceiling that separate us from our neighbors above and below us.

The primary standard for this purpose is ASTM E492: Standard Test Method for Laboratory Measurement of Impact Sound Transmission Through Floor-Ceiling Assemblies Using the Tapping Machine. This standard is used to measure the acoustic performance of the floor-ceiling assembly that separates a room from the room below it. The floor-ceiling assembly is generally comprised of several types of items: floor finish, underlayment, structure such as joists or a concrete slab, insulation, ceiling board or tiles, etc. The ASTM E492 test method aims to measure how good the specimen is at reducing the transmission of impact noise from the upper room into the lower room. The single-number rating produced by an ASTM E492 test (calculated with reference to ASTM E989) is the Impact Insulation Class (IIC). A higher IIC rating corresponds with higher acoustical performance. IIC 50 is the minimum required performance in the International Building Code (IBC), though acoustical consultants often recommend higher IIC ratings to obtain satisfactory impact isolation.

The ASTM E492 test is similar to the ASTM E90 test (which yields an STC rating) in that both tests aim to characterize the performance of a building partition (in the case of E492, specifically floor-ceiling systems). Since these tests measure the performance of entire assemblies, they can be applied to a wide variety of building; however, each E492 test represents the performance of the ENTIRE assembly rather than any one piece within the assembly. The difference between the two tests lies in the noise source; ASTM E90 utilizes loudspeakers to produce airborne noise, whereas E492 utilizes a specifically designed tapping machine to generate impacts on the floor of the upper room.

The general procedure for the test is fairly simple – the tapping machine (a box with 5 hammers that independently and repeatedly fall on the floor) is placed in multiple positions on the floor in the upper room, and the noise that is transmitted through the system into the lower room is measured. The positions of the tapping machine are dictated by the standard to improve the reproducibility between comparative tests and are designed to excite the floor in specific ways. Different floor-ceiling assemblies will respond differently depending on their structural makeup. For instance, the response of a typical joist floor will vary depending on if the impact is directly above a joist or centered between two joists. The various prescribed positions of the tapping machine are designed to fall both on and between structural support members (if they exist).

A recent development within impact noise testing is the development of high-frequency and low-frequency impact noise metrics. Over years of collecting and analyzing ASTM E492 test data, it has become clear that the impact performance of floor-ceiling structures is a multi-domain problem; the floor finish/underlayment layer (installed on top of the structural system) has large effects on the high-frequency domain, but very little impact (pun intended) on the performance below 315-400 Hz. On the other hand, the lower frequency performance of a system (250 Hz and below) is primarily controlled by the resonances of the structural system itself, and seems to only be affected by large-scale changes to the system such as cavity depth, total mass, structural stiffness, addition of ceiling panel/isolation layers. As a result of these discoveries, two new metrics were developed to characterize these two frequency-domain-dependent behaviors: Low-Frequency Impact Insulation Class (LIIC, ASTM E3207) and High-Frequency Impact Insulation Class (HIIC, ASTM E3222).

These two metrics serve as helpful informers to further analyze the impact insulation of a system. If a system’s overall IIC rating is limited in the low 50s, but it is achieving an HIIC rating in the high 60s, for example, the floor topping layer is likely quite high-performing, and the system is being limited by the structure itself and other elements in the assembly. This tells us that a higher IIC rating would be hard to achieve without modifications to the structure itself, significant changes in the ceiling isolation, and/or adding mass to the system. In other words, going down a rabbit hole searching for other floor toppings or underlayments to increase the IIC performance is likely a fruitless task.

Since its creation, the ASTM E492 test method has been the de facto method for analyzing the effectiveness of floor-ceiling assemblies at mitigating impact noise. The innovation of utilizing a standardized tapping machine as an impact source has created a consistent, repeatable way to synthesize common (but much less reproducible) noise sources that are seen in daily life such as footfalls and object drops. This method has also led to the development of ASTM E1007, the field version of this test method, and ASTM E2179, a floor-covering specific offshoot that evaluates the increase in the IIC rating when a floor finish is added to a concrete slab. Current work is also underway for the development of a laboratory test method that measures the amount of noise within the room where the impacts occur. This is different from ASTM E492 which measures the noise from impacts in the room BELOW where the impacts occur. This new standard will be useful for evaluating the effects of flooring on the noise generated by footfalls and rolling objects in places like hotel and hospital corridors.

ASTM E492 has been around for many decades and without it our buildings would be far noisier than they are today. However, E492 is not a perfect test method and meeting the IBC code minimum of IIC 50 does not guarantee a satisfactory level of noise reduction. A recent interlaboratory study (ILS) has shown that there is significant variation in the IIC ratings different labs obtain when conducting an ASTM E492 test on a bare six-inch concrete slab. The ILS is part of an effort in ASTM to improve E492 and to reduce the variability in test results. There are also efforts to develop new test methods that better characterize the impact isolation of an assembly and that are more correlated with our perception of impact noise. If you are interested in these efforts, please consider joining the ASTM E33 committee on acoustics.

About the authors:

Jordan Strybos is a Project Engineer at Intertek’s acoustical testing facility in York, PA. He oversees the Vertical Transmission (VT) test chambers, specifically focusing on floor/ceiling acoustics. Jordan has been overseeing the operations of York’s VT chambers for over 10 years and has been heavily involved in the ASTM E33 committee since 2018, chairing several task groups and serving as subcommittee vice-chair and secretary for the E33.10 subcommittee on Impact Noise and Vibration. The lab at Intertek-York is a state-of-the-art facility that provides highly-efficient testing, excelling in both project-specific test programs and broader-ranging research projects. The VT chambers at Intertek-York offers a lab testing environment for anyone interested in conducting testing per ASTM E90, ASTM E492, ASTM E2179, ASTM E1222, ASTM E1414, ISO 10140, and ISO 15665.

Mike Raley is the Director of Engineering at PAC International and the Director of the Oregon Acoustic Research Laboratory at the University of Oregon. Mike has worked as an acoustician for 17 years and has been heavily involved with the ASTM E33 committee since 2018. He is currently the membership secretary of E33, the secretary of E33.05, the co-chair of the ILS on E90 for walls and E90/E492 for floor/ceiling assemblies, and active in many task groups, especially those focused on measuring the transmission of impact and airborne sound.

PAC International is a manufacturer of high-performance noise control products including spring ceiling hangers, floating floor isolators, and original sound isolation clip, the RSIC-1. PAC is committed to supporting the acoustic community through extensive acoustical testing and involvement in ASTM, INCE, ASA, and NCAC.

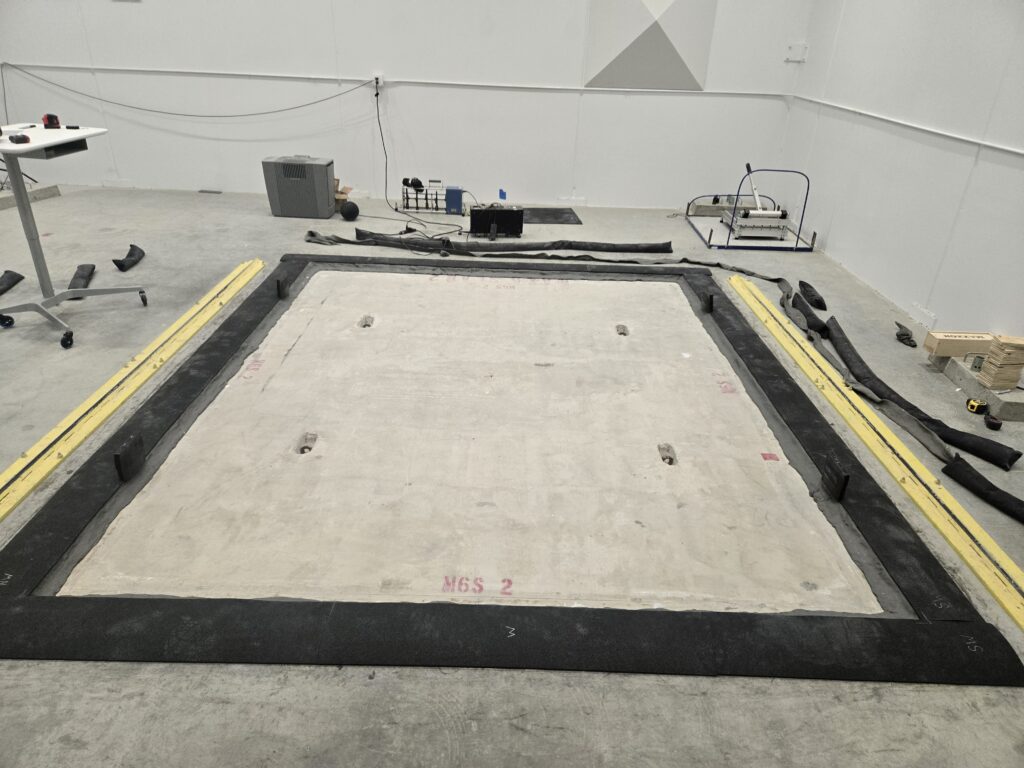

The Oregon Acoustic Research Laboratory (OARL) at the University of Oregon is a new world-class floor-ceiling testing facility set to open in 2027. The test chambers have been designed by Jerry Lilly to provide adequate modal density down to 50Hz and to provide exceptionally high flanking limits for both airborne and impact noise tests. OARL is part of a large innovation hub in Portland focused on supporting the expansion of the mass timber industry.