Setting the Standard: AHRI’s Role in Shaping the Sound of HVACR

Authors:

Jacob (Cobi) Waxman, Standards Manager, Standards, Air-Conditioning, Heating,

and Refrigeration Institute (AHRI)

Derrick Knight, Lead Acoustic Engineer, Trane Technologies

Paul Bauch, Engineering Manager, Sound & Vibration, Johnson Controls

Regan Spencer, Communications Manager, AHRI

Ali Burke, Graphic Artist, AHRI

When you step into a library, a hotel room, or an office building, you may not think twice about the hum of an air handler or the drone of a rooftop chiller. Yet those background sounds, and whether they fade unnoticed or intrude on daily life, are shaped in large part by decades of work from the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) and its member companies. AHRI’s sound standards give manufacturers, engineers, regulators, and building owners a common framework to measure, compare, and address equipment noise.

A History of Sound at AHRI

AHRI’s involvement in acoustics standards dates back more than 60 years. In 1959, the then-Air-Conditioning and Refrigeration Institute formed a committee on sound to address rising public concern over noise created by HVACR equipment. By 1967, AHRI had issued its first sound rating standard: ARI Standard 270–1967, Standard for Sound Rating of Outdoor Unitary Equipment. A few years later came ARI Standard 575–1973 Method of Measuring Machinery Sound Within Equipment Rooms.

Fast forward to today, and AHRI’s Sound Standards Technical Committee (STC) now oversees an expanding portfolio of 14 active standards that are developed and updated to address evolving industry needs.

Why Sound Standards Matter

Why do sound standards exist in the first place? The answer is two-fold: to ensure fair competition among manufacturers and to provide reliable data that designers and regulators can use to make good decisions.

Left to their own devices, each manufacturer might test and report sound levels in its own way, making “apples-to-apples” comparisons nearly impossible. AHRI standards solve that problem by outlining consistent test conditions and reporting methods, outlining requirements for collecting data through several test methods, including reverberation rooms, free-field setups, or sound intensity mapping.

An often-understated advantage of product sound rating standards, specifically, is that equipment manufacturers are encouraged to collect substantial sound data on their products to compete. This price of entry into the market pushes manufacturers to invest in testing facilities that are also used for product development projects, leading to quieter designs and a variety of noise control features. As more AHRI sound standards are adopted, companies will follow with lower-noise products to compete, pushing the industry forward.

Categories of AHRI Standards

AHRI’s sound standards fall into three main categories:

- Test Standards, which specify laboratory methods and the required details for testing setup.

- Rating Standards, which cover the scope of equipment, operating conditions, and reporting requirements. These standards make the so-called “apples-to-apples” comparison possible by establishing a benchmark approach that can achieve reliable results across manufacturers.

- Application Standards, which provide guidance on how to use ratings data for specific installations, accounting for both environmental and construction detail to help predict what occupants will actually hear. These standards are often used to predict sound pressure levels for a given installation where rating standards all produce sound power levels.

Test Standards

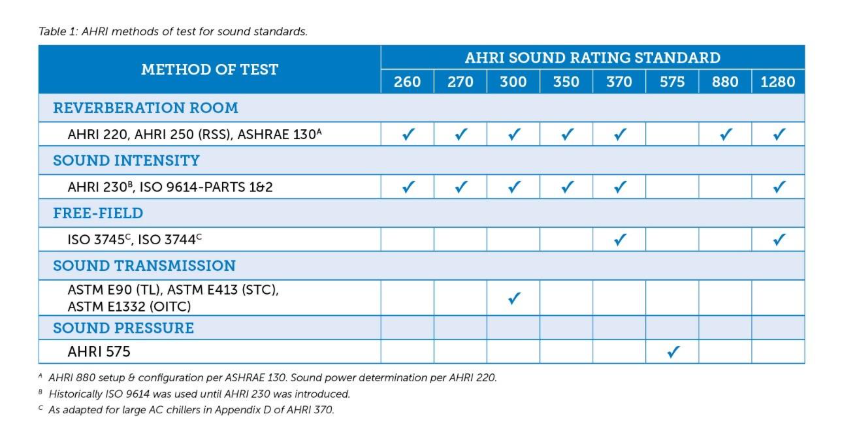

Ratings for HVAC equipment start with a basic understanding of how the equipment is tested. There are three general categories of test standards: comparison method in a reverberation room, sound intensity, and sound pressure in a free-field. Table 1 is an overview of all the test standards referenced by AHRI sound standards.

One of AHRI’s objectives is to ensure that all AHRI sound standards methods-of-test have equivalent uncertainty (reproducibility). Thus, when these standards are referenced, there is no question about the “grade” or quality of the test data. Figure 1 shows several test environments and methods of test that satisfy AHRI standards.

Ratings Standards

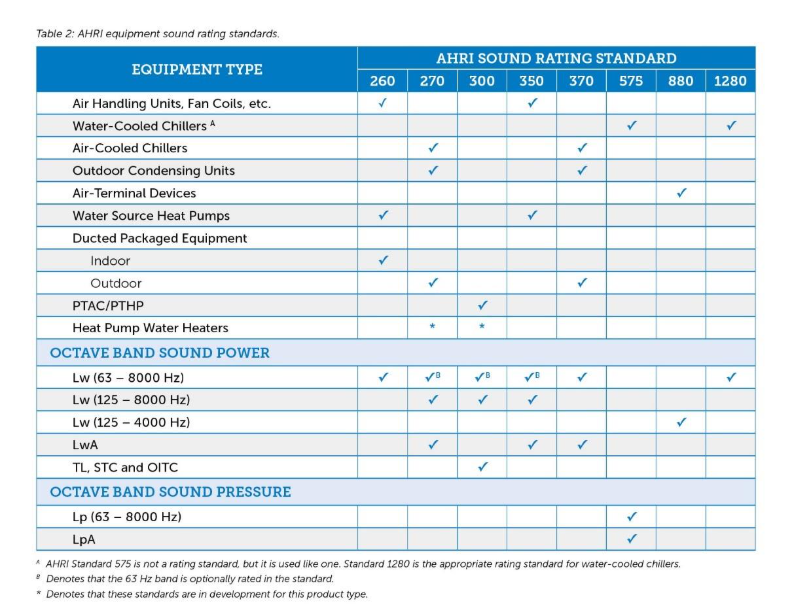

AHRI ratings standards consider variable operating conditions. Determination and stability of the operating point can be a significant cause of variability in sound test data between laboratories. Catalog sound ratings are required at the standard thermal rating conditions for the type of equipment. Some standards, such as AHRI 260, offer guidance on reporting sound across the full operating range of the unit.

Application Standards

Application standards are often used to predict sound pressure levels (what you hear) for a given installation, whereas rating standards all produce sound power levels (what the equipment emits). AHRI Standards 275, 575, and 885 provide a good starting point for application guidance. For more detailed analyses refer to the ASHRAE Application Handbook or a qualified acoustic consultant.

Discerning readers might recognize that AHRI Standard 575 (SI/I-P), Method of Measuring Machinery Sound Within an Equipment Space, is an applications standard, even though it is included in the rating standard table. AHRI Standard 575 is the only rating standard that reports sound pressure levels. It was originally written to define a method of measuring the sound pressure level in equipment rooms, where the risk of hearing loss was the primary concern. AHRI Standard 575, which has since been replaced in part by AHRI Standard 1280, remains a useful tool for measuring noise in the field.

Sound Power vs. Sound Pressure

Standards must consider both sound pressure and sound power. When determining sound pressure, manufacturers must account for the environment in which the equipment is being used and the listeners’ distance from the equipment, neither of which they can control. However, when equipment manufacturers report sound power at the selected operating point, building designers are then able to use that data to predict sound pressure levels in the unique building being designed.

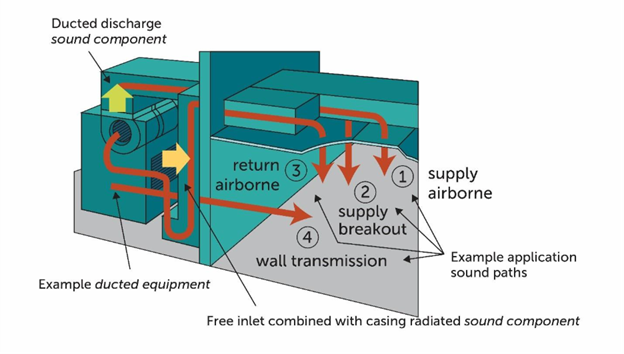

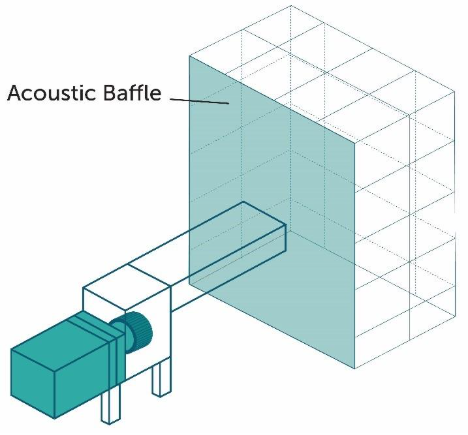

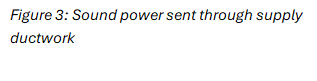

AHRI Standard 260 defines many sound components so as to standardize how manufacturers separate out the sound power around the idea of sound paths. That way, designers can propagate each sound power component along its unique sound path to a listener. The paths are added into a single value, but can then be individually optimized with changes to the path design to focus attenuation on the loudest path. Figure 2 shows an example of how AHRI Standard 260 data could be used to predict sound in an occupied space.

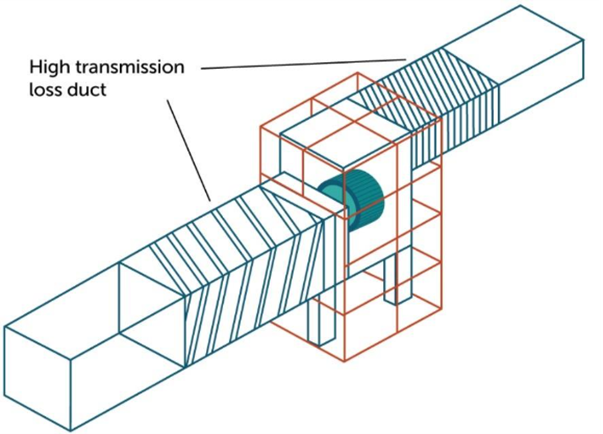

For example, air handlers are often found far from listeners. Measuring the total power emitted from an air handler is possible, but not very useful for building designers. Some portion of the sound power will be sent to the space via the supply ductwork (Figure 3), another portion will be sent via the return ductwork (Figure 4), and some radiates directly from the casing (Figure 5). Each of these sound paths will have different effects, which need to be accounted for in building design.

What’s Next?

As mentioned above, AHRI’s portfolio of active standards regularly evolves to meet industry needs. To do this, the member companies working to maintain AHRI sound standards are also engaged with customers and design engineers to make sure the industry delivers the information needed for intelligent design decisions. As the population and economy require new structures, we are able adapt to promote both efficiency and human comfort.

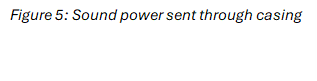

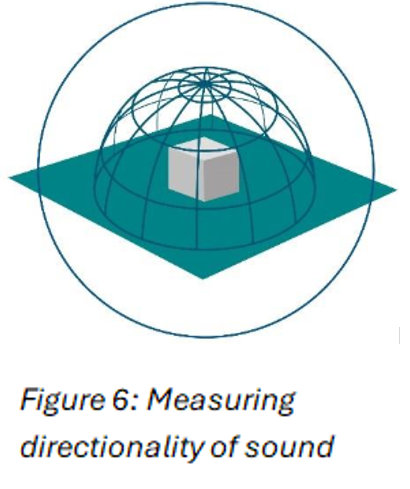

Recently, AHRI and member companies have begun exploring the idea of directionality in sound, specifically in relation to AHRI 370, which measures total sound power emission of large outdoor equipment (Figure 6) that can have significant community impact. There is a growing demand for this type of information as the landscape of new building construction changes. For example, consider dozens of air-cooled chillers installed on the roof of a data center (Figure 7). If sound propagates unevenly, designers need to know, so that they can build sound attenuation to meet noise codes.

However, large sound blocking walls are expensive and greatly increase the embodied carbon both from the construction of a sound wall and the building’s enhancement required to support the added weight. In addition, tall sound walls can impede the airflow of the chillers, reducing their efficiency. This means it is essential for building designers to have access to directionally accurate sound power data to optimize designs.

These new efforts reflect the continuous commitment of AHRI and its member companies in advancing the field of sound standards. As the industry adapts to meet the changing needs of building design and other emerging fields, AHRI’s work on sound will remain an important component in ensuring that decisions are made with reliable data that promotes innovation and intelligent design.

About AHRI

A North American association with global interests and services, AHRI serves its membership of 325-plus HVACR and water heating equipment manufacturers through operations in the United States, Canada, China, UAE, India, Mexico, and Singapore.

AHRI members manufacture quality, efficient, and innovative HVACR equipment and components for sale around the world. These products account for more than 90 percent of the residential and commercial equipment manufactured and sold in North America.

Through AHRI’s certification, standards, advocacy, and analytics programs and more, we help ensure safety, comfort, and productivity for all. For more information on AHRI’s portfolio of 100+ performance standards and guidelines, visit our website: ahrinet.org/standards.