The Search for the Top (10) Industrial Engineering Noise Controls

By Bryan Beamer

Background

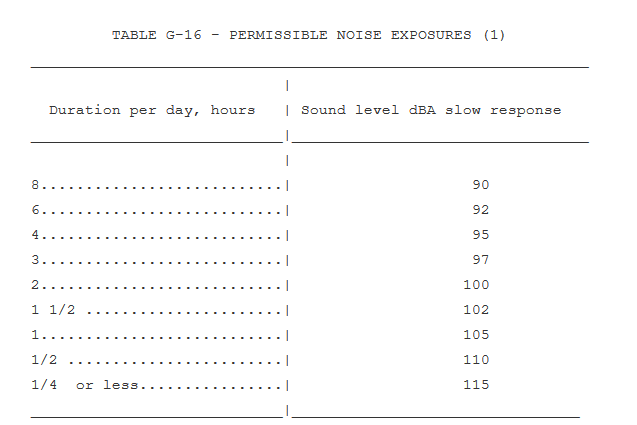

The implementation of engineering noise controls to protect workers from the harmful effects of noise is a requirement of the US Occupational Safety and Health Administration (OSHA). Specifically, 29 CFR 1910.95(b)(1), which covers General Industry, states “When employees are subjected to sound exceeding those listed in Table G-16, feasible administrative or engineering controls shall be utilized (see the figure below).” Regulations for the Construction Industry are similar (see 29 CFR 1926.52[b]).

US Occupational Safety and Health Administration

In addition to OSHA compliance, there are many good reasons to implement engineering noise controls. Consider these facts from the National Institute for Occupational Safety and Health (NIOSH 2019) “Occupational Hearing Loss Surveillance” web page:

- In the United States, hearing loss is the third-most common chronic physical condition among adults after hypertension and arthritis.

- About 12% of the U.S. working population has hearing difficulty.

- About 24% of the hearing difficulty among U.S. workers is caused by occupational exposures.

- About 8% of the U.S. working population has tinnitus (‘ringing in the ears’) and 4% has both hearing difficulty and tinnitus.

- About 22 million workers are exposed to hazardous noise each year.

Despite the fact that OSHA requires implementation of feasible engineering controls, personal protective equipment (PPE) has traditionally been relied upon to address noise in the workplace. Unfortunately, this strategy often fails due to poorly chosen, or incorrectly or sporadically worn hearing protectors. To emphasize this point, consider that about 31 percent of noise-exposed construction workers and 24 percent of noise-exposed manufacturing workers report not wearing hearing protection. Additionally, 22–56 percent of noise-exposed services workers report not wearing hearing protection, depending on the subsector (NIOSH 2019).

To encourage the consideration and implementation of engineering noise controls in the American workplace, NIOSH is currently working to promote the use of straightforward, easy-to-implement noise controls. The strategy is to simplify implementing noise controls by emphasizing “Top 10 Engineering Noise Controls” on a future web resource entitled How to Protect Workers from Noise. This web resource will be aimed at safety professionals who may not have a background in engineering. This top 10 list is not meant to be comprehensive or replace the services of certified noise control engineers, but rather to give safety professionals and employers a starting point. The goal at NIOSH is to encourage the idea that engineering noise controls need not be overly complicated or difficult to implement.

Useful Resources

Reviewing resources to inform the top 10 engineering noise controls list makes it clear that not much has changed over the last several decades. In fact, the publications listed below largely reiterate the same basic principles. Considering that the noise control principles at the heart of these publications are based on straightforward physics, it makes sense that the classics never change. One caveat: the publications listed below are not meant to be a comprehensive list of the noise control engineering literature. Instead, these resources are a synopsis of publications that influenced NIOSH’s current efforts to establish a basic engineering noise controls list.

Some of the early work to promote industrial noise controls was published in the wake of the Occupational Safety and Health Act of 1970. For instance, two NIOSH reports from the 1970s include fundamental information and several case studies:

- The NIOSH technical report Industrial Noise Control Manual, published in June 1975: https://www.cdc.gov/niosh/docs/75-183/default.html

- Another version with excellent case histories was published by NIOSH in 1978: https://www.cdc.gov/niosh/docs/79-117/default.html

Also, in the 1970s, Brüel & Kjaer published the extremely useful and widely referred to Swedish-language resource Noise Control, which, according to the Institute of Noise Control Engineering website, was originally prepared by Stig Ingemansson (Arbetarskyddsfonden [Swedish Work Environment Fund] 1977). This publication became the basis for many English-language resources over the next several years. For example, much of the information was published as a 15-part series in Noise News International from June 1994 (vol. 2, no. 2) to June 1999 (vol. 7, no. 2). Furthermore, the Swedish publication was translated to English and disseminated by the US Department of Labor in 1980 under the title NOISE CONTROL: A Guide for Workers and Employers. If you have a paper copy of this document, count yourself lucky. This guide, based on the original Swedish document, is the epitome of straightforward, easy-to-implement noise control techniques. Fortunately, the nonprofit Noise Pollution Clearinghouse has provided the web version of this resource online (see https://www.nonoise.org/hearing/noisecon/noisecon.htm).

Years later, Hansen and Goelzer (1996) published the document “Engineering Noise Control,” which uses many of the same pictures and principles as the original Swedish Work Fund publication. However, there is quite a bit more development and discussion of the physics and noise control principles, making it a good reference for noise control engineers. Several years later, this work formed the basis of the World Health Organization (2001) publication Occupational Exposure to Noise: Evaluation, Prevention and Control. This report is on the technical side and is suitable as an engineering reference.

Since the early 2000s, several excellent resources regarding engineering controls aimed at nonengineers have been disseminated by our colleagues in Britain and Australia. For instance, the document “Top 10 Noise Control Techniques” is a concise and useful document found on the British Health and Safety Executive (n.d.) website. Safe Work Australia (2019) presents many simple-to-implement methods for keeping noise levels down, on their website. Furthermore, Safe Work Australia published the beneficial reference document “Control Guide—Management of Noise at Work” in 1991, reprinted in 2004 (National Occupational Health and Safety Commission 2004). Another beneficial resource is “Top 10 Noise Control Techniques: 2015,” by Peter Wilson (2016), published in Acoustics Australia.

Our Current Top 10

Below are the 10 examples currently under consideration for inclusion on the “Top 10 Noise Controls” section of the NIOSH web resource How to Protect Workers from Noise. As stated previously, this information is neither meant to be comprehensive nor to replace the services of certified noise control engineers. Instead, the list is meant to give safety professionals and employers a starting place for their attempts to create a quieter workplace. These examples are derived primarily from the Department of Labor document, NOISE CONTROL: A Guide for Workers and Employers, as translated from the original Swedish Work Environment Fund document of 1977. The images are taken directly from the 1980 Department of Labor publication; new, updated illustrations will be produced for NIOSH’s future web resource.

1. Reduce Speed of Moving Parts

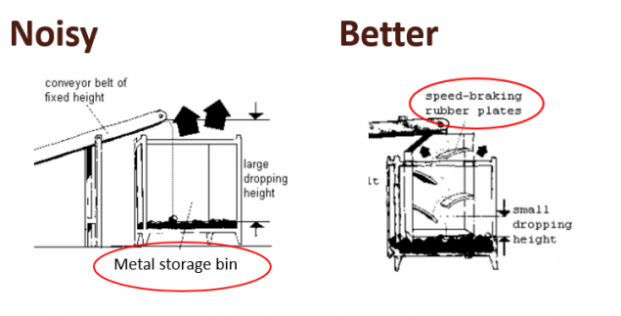

The sound energy produced when parts or machinery are in motion is often reduced by slower speeds. For example, slower fans with larger blades move the same volume of air but at a reduced speed.

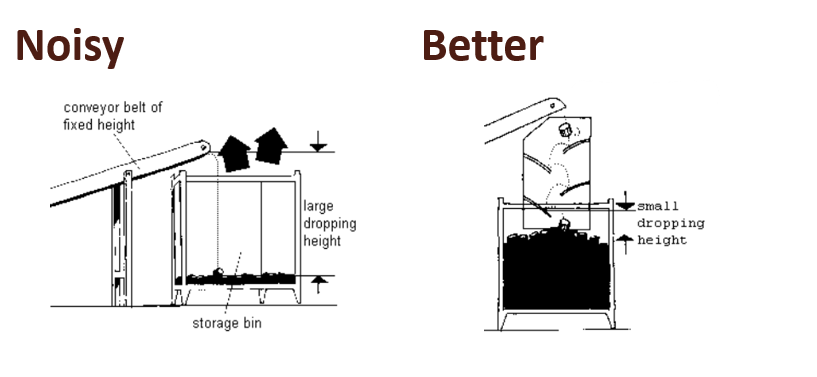

Decrease impact noise of falling parts by decreasing falling distance. See example below.

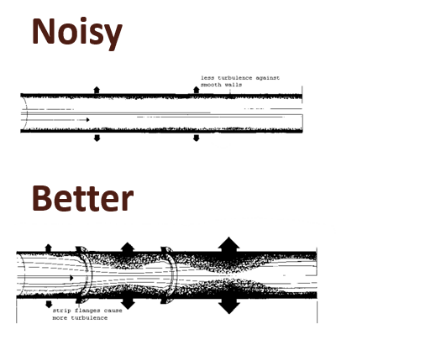

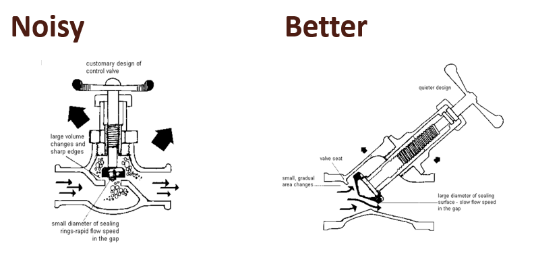

2. Eliminate Restricted Flow in Pipes and Ducts

Restricted flow in ducts and pipes can create extra turbulence that will increase noise. Eliminating obstructions can reduce this noise. Workplace examples include:

3. Reduce Impact Forces

Noise created by impact forces is lessened when softer materials are used at the point of impact. For example, replace metal parts with quieter plastic parts.

4. Reduce Vibrating Parts and Surfaces

Sound is produced when solid surfaces vibrate. This effect can be lessened by reducing the vibrating surface area.

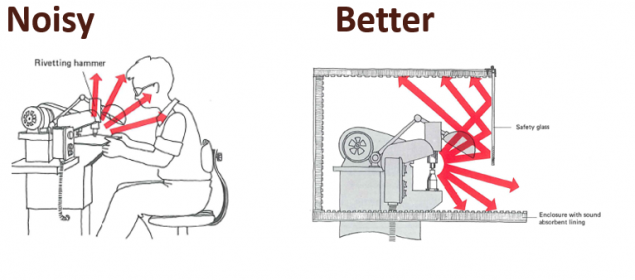

5. Add Barriers and Sound Absorption for Middle to High Frequencies

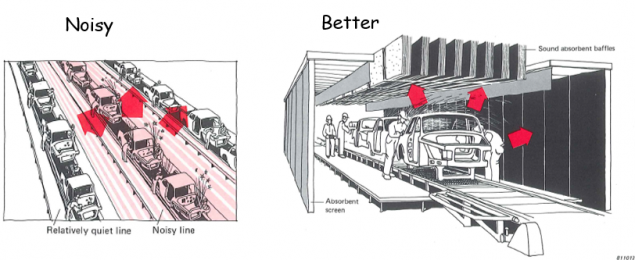

High pitch sounds (about 2000 Hz and higher), like whistles and the high end of a piano, are more easily reflected by barriers. Examples in the workplace include the following:

- Riveting machinery

- Grinding operations

- Machine cutting

- Compressed air cleaning

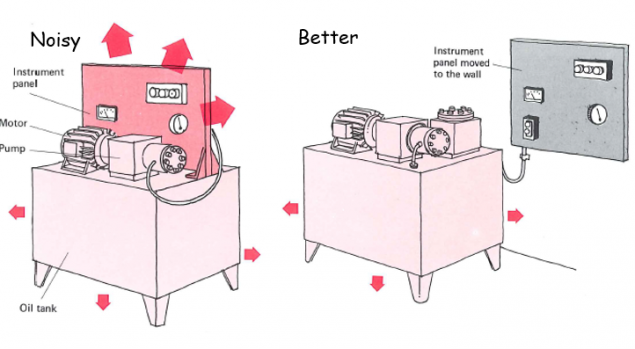

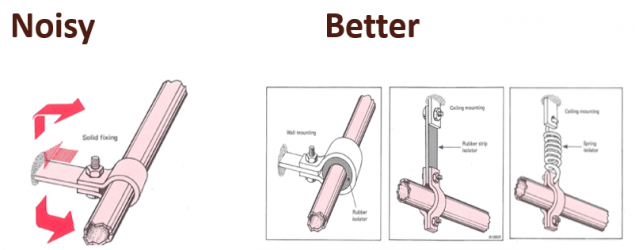

6. Use Anti-vibration Connectors

Vibrating equipment is not only noisy by itself but also can send vibrations to connected walls and ceilings. Isolating these noise sources will decrease radiated sound.

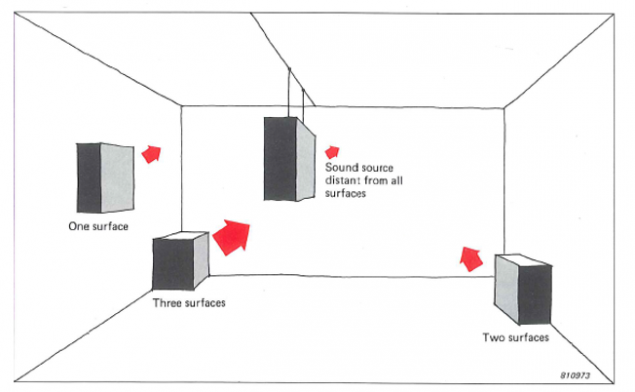

7. Keep Noisy Machinery Away from Walls/Sound-Reflective Surfaces

The closer to a hard surface a sound source is placed, the greater the noise it will radiate. The worst placement is in corners near three surfaces. The best placement is away from the walls.

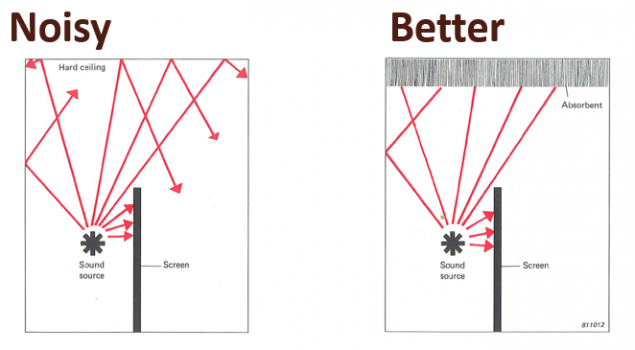

8. Combine Sound Shields with Sound-Absorbing Ceilings

When using barriers or walls, reflected sound should be absorbed with sound-absorbing ceilings. Best practices when using sound shields between noise sources and workers:

- Barriers should be constructed from a dense material, such as brick or sheet steel, although chipboard and plasterboard can also be used.

- Screens and barriers work best when they are placed close to the noise source or close to the people you are trying to protect. The higher and wider they are, the more effective they are likely to be.

- Screens and barriers work best in rooms with either high or sound-absorbent ceilings.

- Covering the barrier or screen with noise-absorbing material on the side facing the noise source will have the added advantage of reducing the sound reflected back toward the noise source. Sound builds up in any room, so it is beneficial to reduce that build-up.

- Keep in mind that screens and barriers may not work well for low frequencies.

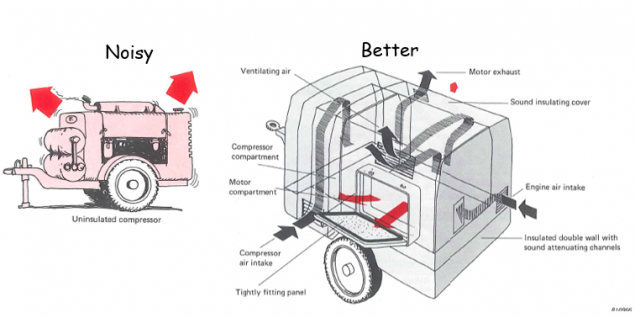

9. Seal Enclosures for Low-Frequency Sources

Low-frequency noise radiates around corners and through holes and then continues to travel in all directions. A complete enclosure of damped material lined with sound-absorbent material will help. All doors and openings should close tightly.

10. Use Sound Absorption for All Enclosures and Barriers

Best practices for the use of sound-absorbing materials:

- Heavy, dense building materials like brick, concrete, and mineral wool have better sound-absorbing properties than light ones; think materials like drywall or foam insulation.

- Vendors of sound-absorbing materials can help you analyze your noise levels and make recommendations regarding commercially available products.

- Line enclosures and barriers with sound absorbers on the noisy side.

- Microperforated plates can have good sound absorption when correctly designed. These can be made of stainless steel and are therefore options where barriers and enclosures need to be cleaned with high temperature/pressure areas like cleanrooms and food production facilities.

Next Steps

At NIOSH it is our goal is to protect workers from occupational hazards, including excessive workplace noise. Part of achieving our goal is to promote the understanding and appropriate use of engineering noise controls like those in this article. Several strategies to promote the implementation of engineering noise controls are therefore under consideration, including the following:

- Publishing a top 10 noise controls list on a NIOSH website called How to Protect Workers from Noise.

- Developing in-person and online training modules to complement the website aimed at safety professionals with little or no noise control experience.

- Working with INCE to develop training modules for safety professionals and non-noise control engineers.

- Working with INCE to develop professional development courses for noise control engineers who have a solid basis in noise and its control but don’t regularly practice noise control in an industrial setting.

Determining which noise controls might be the most useful and presenting them in a straightforward way is an ongoing process. If you have any constructive feedback, please don’t hesitate to contact the author, Bryan Beamer, at zmy4@cdc.gov.

Disclaimer

The findings and conclusions in this report are those of the author and do not necessarily represent the official position of the NIOSH, Centers for Disease Control and Prevention.

References

Arbetarskyddsfonden (Swedish Work Environment Fund). 1977. Noise Control. [In Swedish.] Stockholm: Arbetarskyddsfonden (now Rådet för Arbetslivsforskning).

Goelzer, B., and Hansen, C. 1996. “Engineering Noise Control.” Journal of the Acoustical Society of America 100. https://www.researchgate.net/publication/228584816_Engineering_Noise_Control. See also https://www.who.int/occupational_health/publications/noise10.pdf.

Health and Safety Executive. n.d. “Top 10 Noise Control Techniques.” Accessed February 2020. https://www.hse.gov.uk/pubns/top10noise.pdf.

National Institute for Occupational Safety and Health. 1975. Industrial Control Manual Publication Number 75-183. Cincinnati: DHHS. https://www.cdc.gov/niosh/docs/75-183/default.html.

———. 1978. Industrial Noise Control Manual Publication Number 79-117. Cincinnati: DHHS. https://www.cdc.gov/niosh/docs/79-117/default.html.

———. 2019. Occupational Hearing Loss (OHL) Surveillance. December 9, 2019. https://www.cdc.gov/niosh/topics/ohl/.

National Occupational Health and Safety Commission. 2004. National Code of Practice for Noise Management at Work: Control Guide. [NOHSC: 2009(2004)]. 3rd ed. Canberra: National Occupational Health and Safety Commission. https://www.safeworkaustralia.gov.au/system/files/documents/1702/nationalcodeofpractice_noisemanagementandprotectionofhearingatwork_3rd_edition_nohsc2009-2004_pdf.pdf.

Noise Pollution Clearinghouse. n.d. “Noise Control: A Guide for Workers and Employers.” Accessed January 28, 2020. https://www.nonoise.org/hearing/noisecon/noisecon.htm

Safe Work Australia. 2019. “Noise,” section “Easy Ways to Keep Noise Levels Low.” July 29, 2019. https://www.safeworkaustralia.gov.au/noise#easy-ways-to-keep-noise-levels.

US Department of Labor. 1980. Noise Control: A Guide for Workers and Employers. US Department of Labor Occupational Safety and Health Administration.

Wilson, P. 2016. “Top 10 Noise Control Techniques.” Acoustics Australia 44:33–43. https://doi.org/10.1007/s40857-015-0039-y.

World Health Organization. 2001. Occupational Exposure to Noise: Evaluation, Prevention and Control. Edited by Berenice Goelzer, Colin H. Hansen, and Gustav A. Sehrndt. Geneva: World Health Organization. https://www.who.int/occupational_health/publications/noise.pdf?ua=1.