Novel Acoustic Camera Addresses Price-versus-Performance Dilemma

By Seven Bel

Acoustic cameras are widely regarded as powerful tools for the localization of unwanted noise in products and processes. Engineers from product development, manufacturing, and maintenance who are blessed with access to such technology appreciate the added value of visual information for implementing highly effective technical solutions. In addition, engineering managers and product marketers value avoiding costly trial and error as well as securing timely product launches due to increased predictability during product development, respectively.

The Dilemma

Unlike thermal imaging cameras, acoustic cameras have not experienced comparable penetration into the equipment portfolio of engineering departments so far, especially in small- to medium-sized companies. One reason lies in the properties of industrial sound emissions, which are typically low-frequency sounds by nature. In such a situation, a microphone array system with a diameter of at least 1 m is typically required in order to reliably separate multiple sound sources. The acquisition cost of such equipment in the range of €40K+ combined with required expert know-how may result in a customer’s decision to refrain from purchasing. Over the last couple of years, the trend toward mobile acoustic cameras fueled hopes of accessing to sound imaging devices at a more acceptable price. Yet mobile systems with a diameter of about 30 cm are just not capable of delivering the required image quality for typical industrial applications. Bottom line: we cannot outsmart physics easily, and size simply matters.

Introducing a Novel Method of Sound Imaging

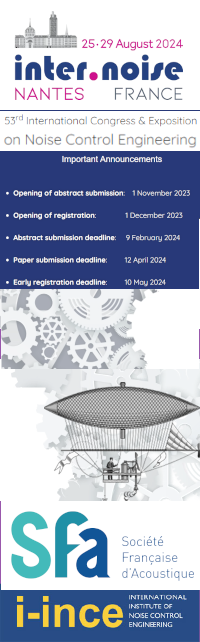

For this reason, Seven Bel has tasked itself with developing a novel acoustic camera that delivers high image quality for industrial applications and offers superb usability and mobility at an affordable price. The enabling technology is a compact rotating sound scanner with a few state-of-the-art digital microphones. Fine spatial sampling of the sound field over a disc with a diameter of up to 1.32 m results in acoustic images with excellent spatial resolution and dynamic range, which drives confidence in the implementation of technical solutions (see figs. 1a and 1b).

The benefit of scanning a large area can be easily seen by performing the following challenging experiment, which is encountered in the testing of drivetrains and engines (see fig. 2). Three loudspeakers are excited with white noise, two of them coherently. The selected frequency band is 2,000 Hz +/− 115 Hz, and a dynamic range of 15 dB is chosen. The center loudspeaker’s gain is +10 dB versus the outer loudspeakers. The large scanner with a diameter of 1.32 m (left image) resolves the right and left speakers sitting 10 dB below the center speaker and shows nice separation of sound sources, while the small scanner with a diameter of 0.5 m (right image) clearly struggles with identifying the three sources. Yet the smaller scanner is particularly useful for measuring medium- to high-frequency sound events in confined spaces.

The sound scanner together with the user’s mobile device and Seven Bel’s number-crunching cloud infrastructure in the background creates a compact high-performance measurement system for the fast analysis of acoustic problems. The developers at Seven Bel paid special attention to designing a massively simplified workflow for measuring and analyzing acoustic images. Automatically generated reports can be easily shared with colleagues, partners, or clients.

The technology has already been successfully demonstrated with products and processes from various industries ranging from automotive to transportation, home appliances, and machinery construction.

Use Cases

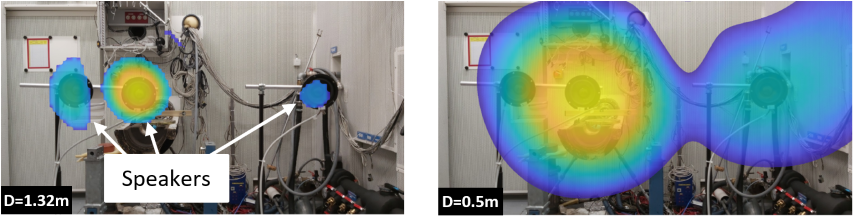

The design of enclosures for machining centers constitutes a particularly challenging task for mechanical engineers. Manufacturers must not only meet corresponding regulatory limits but also increasingly consider the fact that an optimal work environment for the machine operators is guaranteed. Acoustic images support engineers during the development phase in understanding, for instance, the time averaged local sound radiation during a machining process. These insights allow them to build machine housings that are optimal with respect to cost and acoustic effectiveness. In certain cases, sound does not come from where it is initially expected. Grinding the edges of glass plates in glass processing centers leads to critical excitations of eigenfrequencies and eigenmodes of the material being processed. Sound may then not only come from the location where the grinding takes place. Instead, the glass plate being processed acts as a loudspeaker and may dominantly radiate sound from the opposite edge (see fig. 3). It is exactly this sort of insight that gives engineers the confidence to take the right measures when implementing designs for optimal sound reduction.

Another interesting application can be found in the field of automotive engineering, where engineers from vehicle simulation and testing are involved in reconciling simulation models with actual measurement data. Figure 4 shows a motorcycle operated under full load on a roller dynamometer. Engineers are particularly interested in confirming the exact location of sound radiation from the clutch cover in order to update material and geometry parameters in simulation models and thus drive design optimizations.

Seven Bel is currently gearing up to introduce their P50 and P132 sound scanners on the European market. The team is eager to learn more about new potential applications. Contact them today at sevenbel.com and request a demo kit.